Tracking a luxury new construction home through the middle stages reveals the moments where decisions shape long-term performance and livability. On Marco Island, a recently advanced build highlights those turning points: rough trades completed, insulation and board installed, a pool shell in place, exterior paint and roof tiles finished, and the cabinetry now on site. These are the milestones that transform foundations and framing into a home that will stand up to Southwest Florida’s climate and a buyer’s expectations.

What’s Been Completed So Far

At this point in the project the mechanical rough-ins are finished, insulation is installed, and the contractor has hung board and applied a hard coat across walls and ceilings. Cabinets are already in place inside the home and the pool shell is installed outside. Exterior work is well underway with painting and concrete roof tiles applied. Those visible advances mean this is no longer a shell but a space moving quickly toward finish work.

Progress like this shows that a new construction schedule often follows a clear rhythm: structure and weatherproofing first, then mechanical and interior finishes, then final systems and landscaping. In this build the timeline is accelerating toward interior finishes such as countertops, flooring, trim, and pavers.

Why Some Builders Do Things Differently

Local conditions influence construction choices. The builder on this project uses a method that differs from many local competitors: the application of blue board with a full hard coat over walls and ceilings. That extra step adds cost, but it is a deliberate choice aimed at durability.

“It’s a little more expensive but we believe it’s a lot more mold and mildew resistant,”

The hard coat provides a textured, continuous surface that helps keep out moisture and reduces the likelihood of mold growth. In a region that sees frequent rain and occasional power outages, minimizing opportunities for mold and mildew is a practical quality measure for a new construction home.

Timing of Key Systems: Why the AC Comes Later

One common question about new construction sequencing is when the air conditioning is installed. In this build the AC is scheduled to be installed shortly after cabinetry—within a week or two. That sequence avoids unnecessary stress on cabinet materials. Cabinets installed into a home with controlled humidity and temperature are less likely to warp or suffer finish issues.

Putting major systems like HVAC in too early or too late can affect finishes and comfort. Installing the AC during the transition from rough to finish stages gives trades the benefit of a more stable interior environment when sensitive materials are being set and cured.

What Comes Next: the Path to Completion

From this stage forward the project moves through a concentrated period of finish work. The next tasks include:

- Interior painting and surface preparation.

- Countertop templating and installation.

- Flooring installation.

- Trim and millwork.

- Pavers and outdoor hardscape.

The builder expects much of this activity to happen in the coming weeks, with the goal of completing the house in the next few months. That timeline is typical for luxury new construction once the major systems and exterior are in place.

Climate-Specific Considerations for Southwest Florida New Construction

Southwest Florida has its own set of priorities that affect construction choices. Heavy rain, high humidity, and the occasional power interruption demand materials and sequencing that help a home perform well over time.

- Mold resistance: Continuous hard coat and moisture-resistant assemblies reduce mold risk.

- Roofing choices: Concrete roof tiles are common for durability and wind resistance.

- Pool sequencing: Installing the pool shell in the middle of the project is a regional norm that coordinates with structural and finish trades.

Builders experienced in Florida often plan trades and systems around these realities so a home is not only beautiful but resilient.

Opportunity on the Market

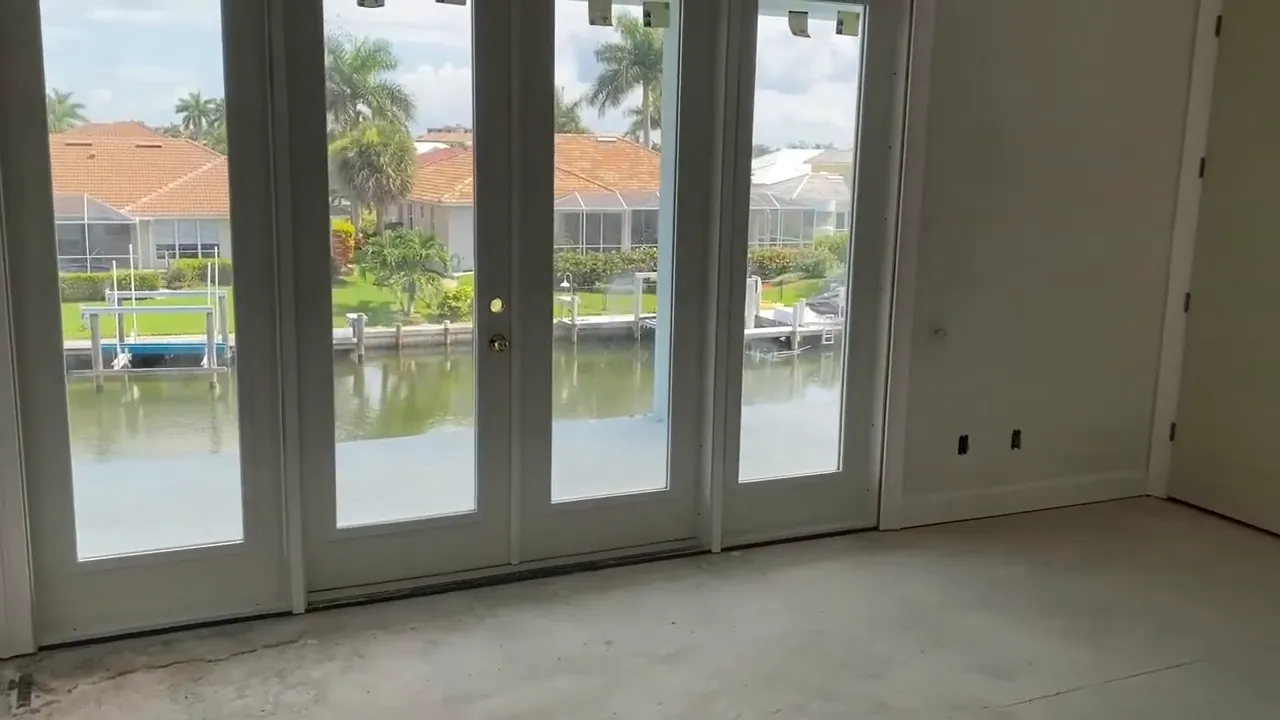

This particular new construction home was originally built for an owner who later decided to sell. At the current stage the home is available at an asking price near $2.7 million, with expansive views and high-end finishes already committed. For buyers looking for a near-complete home that will be finished with custom details, this represents a chance to see selections and construction decisions already made while still stepping into a home before final punch list completion.

How to Evaluate a Mid-Stage New Construction Purchase

For a buyer considering a mid-stage purchase the following checklist helps evaluate value and risk:

- Confirm which materials and finishes are already installed versus those still to be chosen.

- Verify warranty transferability and builder warranty coverage for major systems.

- Inspect sequencing choices such as HVAC installation and moisture-control measures.

- Review permits, inspections, and any documentation of structural and mechanical work.

- Assess exterior finishes and landscaping plans that affect curb appeal and long-term maintenance.

Understanding those elements clarifies what the buyer inherits and what remains under the builder’s control.

Builder Practices that Add Long-Term Value

Certain builder decisions may cost more up front but deliver better performance over time. This project highlights a few such practices:

- Blue board and hard coat: A full hard coat across walls and ceilings for enhanced mold and mildew resistance.

- Concrete roof tiles: Robust roofing that suits local weather patterns.

- Timing of HVAC: Installing air conditioning close to finish work to protect cabinets and finishes.

These choices reflect a focus on long-term durability, not just short-term savings. In regions prone to moisture, that investment often pays dividends in lower maintenance and greater longevity.

FAQs

How long will a home at this stage take to finish?

Once rough trades and exterior work are complete, interior finishes such as painting, countertops, flooring, and trim usually take several weeks to a few months depending on crew availability and the scope of custom work. In this project the target is completion within the next few months.

Why use blue board and a hard coat instead of standard drywall?

A blue board with hard coat creates a continuous, textured surface that is more resistant to mold and mildew. That extra cost helps protect the home in rainy or humid climates and can reduce long-term maintenance issues.

When should the air conditioning be installed during new construction?

Installing the HVAC system after cabinets are in but before final finishes are completed helps control interior humidity and temperature during sensitive finishing stages, preventing warping or finish problems.

What should a buyer check if purchasing a mid-stage new construction home?

Buyers should verify which finishes are installed, confirm warranties, review permits and inspections, and inspect sequencing and moisture-control details. Understanding what remains to be completed and who is responsible is essential.

Is a new construction home a good option for buyers who want customization?

Yes. If selections are still pending, buyers can often customize finishes. Mid-stage purchases may offer a balance between seeing installed work and having input on remaining selections.

Final note

Following a new construction home through the finish stages reveals how material choices and sequencing decisions shape durability and livability. Practical investments—like a hard coat system, appropriate HVAC timing, and durable roofing—help ensure the final home performs well in its environment. For buyers and builders alike, focusing on those details turns a beautiful design into a resilient, long-lasting home.

Contact Us Today! |

|

Providing you the experience you deserve! |

| Click me |