The Bartos Group returns with an upbeat chapter in their ongoing series on Building New Construction in Southwest Florida. In this installment, the host and local builder Jason Bailey of FCI Homes walk viewers through a pivotal milestone: the walls are up. This blog post expands on that walkthrough, translating the on-site details into a clear guide for prospective buyers, local homeowners, and anyone curious about how new homes are built to withstand coastal weather.

Introduction: A Milestone Moment

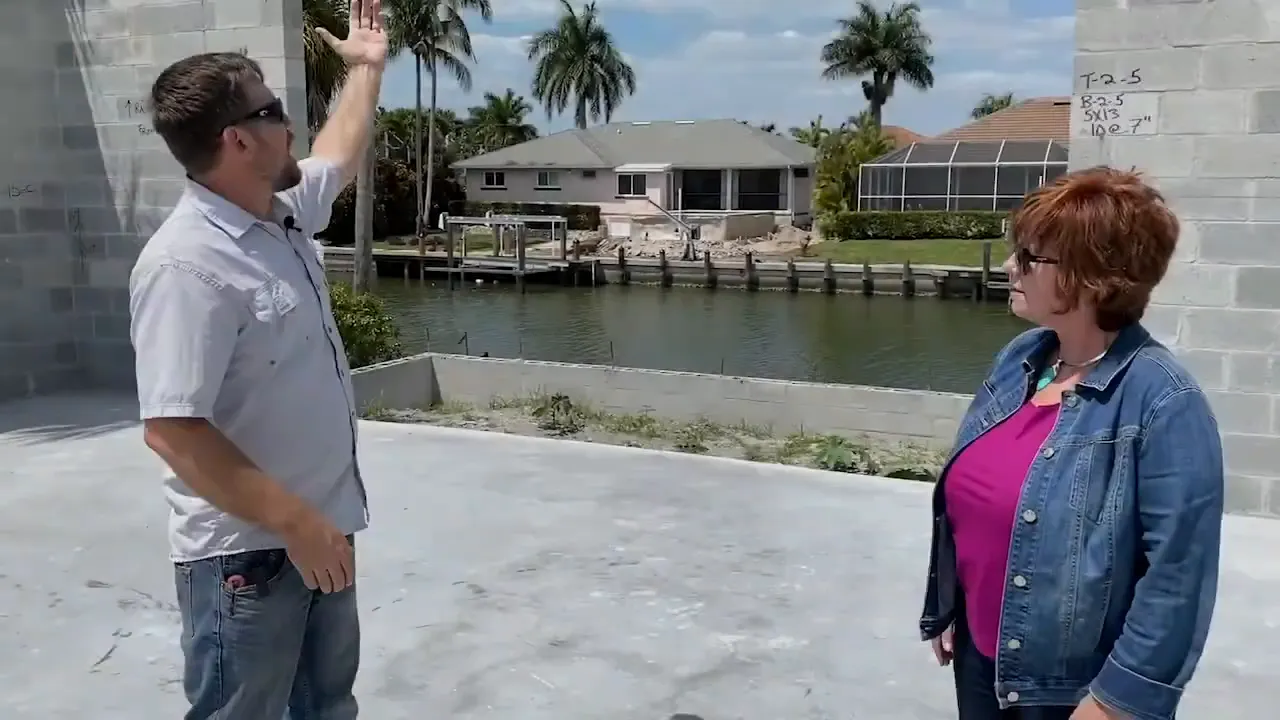

Reaching the “walls up” stage is a major milestone in any residential build. The Bartos Group host highlights this progress with enthusiasm, noting simply: “We have walls.” That phrase captures both excitement and a transition: from below-grade work and foundation to a recognizable structure that begins to look like a future home. In the context of Building New Construction, this step signals that the project is moving from groundwork and utility rough-ins to creating the shell that defines rooms, layout, and massing.

Progress Overview: From Slab to Full Perimeter Tie Beam

When this project was last visited, the crew was preparing to pour the slab. Since then, block walls have been built and reinforced. Jason explains how the construction team ties steel reinforcement from the slab and footer all the way up through the block walls. That reinforcement is then integrated into a cast concrete element known as a tie beam that runs around the entire perimeter of the house.

The tie beam is an essential horizontal member that ties vertical walls together, distributes loads, and forms a continuous stiff ring at the top of the walls. On this project, the team also poured concrete columns in addition to the block walls. Many of the block cells are completely filled with concrete, creating a massively reinforced wall system rather than a hollow wall.

Why Filling Block Cells Matters

- Structural strength: Filled block cells provide compressive and shear capacity to resist vertical and lateral forces.

- Durability: Solid-filled cores reduce long-term maintenance risks compared to hollow blocks.

- Resistance to extreme events: In hurricane-prone areas, filled and reinforced walls help the structure resist uplift and lateral loads.

Hurricane-Ready Features: Truss Straps and Tied-Down Roof Systems

One of the most visible items on the tie beam was a row of metal truss straps. These are small but critical connectors that bind the roof trusses to the top of the tie beam and wall system. Jason emphasizes the role these straps play: when trusses for the roof (and for a potential second floor) are installed, every truss will be strapped and held down.

“All of that stuff gets strapped and held down so if there’s hurricanes, tornadoes, anything — this stuff’s not going anywhere.”

That direct connection—truss to strap to tie beam to foundation—creates a continuous load path from roof to ground. For Building New Construction in coastal regions, establishing that continuous load path is not optional; it’s essential to meeting windborne debris, uplift, and hurricane design requirements. Homes built this way have a far better chance of remaining intact during severe weather.

Outdoor Living: Pools, Spas, and Stem Walls

Beyond the covered lanai, the site shows a significant area of excavated earth where future exterior amenities will be installed. On this lot, the team plans a pool, a spa, and a surrounding pool deck. The pool boundary is formed by another stem wall—essentially a shallow perimeter wall that defines the pool footprint and is reinforced with filled steel cells similar to the main house stem walls.

Once the pool shell goes in and all plumbing is roughed, the crew will cover those utilities and pour the surrounding deck slab. This deck slab ties into the same structural system so that the whole assembly is a unified, durable platform. Jason notes plainly: “These babies aren’t going anywhere. We have a storm—they can’t push away with water, they can’t pull away with the wind.”

Why Local Building Practices Matter in Southwest Florida

Building New Construction in Southwest Florida requires specialized methods due to unique environmental challenges: high wind loads, storm surge potential, and a salt-laden atmosphere. The approach used by FCI Homes on this job reflects those priorities.

- Reinforced concrete and filled masonry: These materials resist wind and water better than many lightweight alternatives.

- Continuous tie beams and straps: Create a robust structural load path from roof to foundation.

- Careful integration of outdoor elements: Pools, lanais, and decks are tied back into the home’s structural system, reducing risk of differential movement or failure during storms.

For a buyer or homeowner unfamiliar with local practices, the visible features—filled block cells, tie beams, truss straps, poured columns, and stem walls—are indicators that the home is being built with longevity and safety in mind.

What to Expect Next in Construction

Jason hints at the next major phase: once the tie beam and truss straps are in place, the trusses and roof sheathing will be installed, followed by roof coverings, windows and doors, and exterior finishes. Inside, the mechanical, electrical, and plumbing rough-ins will continue, but the visible transformation will be the roof and the house becoming fully enclosed.

Enclosure is a watershed moment in Building New Construction—it protects the interior from the elements and allows interior trades to proceed without weather delays. From a buyer’s perspective, this phase often marks when progress becomes most tangible and scheduling for inspections, selections, and move-in dates gains clarity.

Practical Advice for Buyers Considering New Construction

For anyone embarking on a Building New Construction project—especially in hurricane-prone regions—there are practical steps to take and questions to ask:

- Verify materials and methods: Ask whether block cells will be filled and where reinforcement will be placed.

- Confirm hurricane-resistant details: Request specifics on truss straps, roof-to-wall connections, and tie beam continuity.

- Understand pool and exterior ties: Ensure pool stem walls and decks are structurally integrated with the house where appropriate.

- Request periodic updates and photos: Site visits and photos at each milestone help track quality and progress.

- Review warranties and builder credentials: Choose a builder with proven local experience in Building New Construction and coastal conditions.

Builder Spotlight: FCI Homes and Local Expertise

FCI Homes, represented on this job by Jason Bailey, demonstrates a building philosophy tuned to the region. The Bartos Group highlights their collaboration with local builders to ensure clients receive homes designed and built for the environment. That local expertise—from materials to connections to sequencing—matters when designing resilient, comfortable coastal homes.

Key Takeaways

- “We have walls” is more than an update—it’s a transition into the most visible phase of construction.

- Filled block cells, tie beams, poured columns, and truss straps are core elements in Building New Construction in hurricane-prone areas.

- Outdoor amenities like pools are not just decorative; their structural integration with the house strengthens overall durability.

- Buyers should prioritize builders with local experience and ask for specifics on structural reinforcement and weather-resilience measures.

Frequently Asked Questions (FAQ)

Q: What does “tie beam” mean and why is it important?

A tie beam is a cast concrete beam that runs around the top of the walls, tying vertical elements together. It distributes loads and creates continuity in the wall system, which is especially important for resisting wind uplift and lateral forces in coastal construction.

Q: Why are some block walls filled solid with concrete?

Filling block walls with concrete, often in conjunction with vertical rebar, increases the compressive strength and shear resistance of the wall. This technique is commonly used in Building New Construction where durability and storm-resistance are priorities.

Q: What purpose do metal truss straps serve?

Metal truss straps connect roof trusses to the top of the wall or tie beam. They provide uplift resistance, preventing the roof from being lifted off during high wind events. Properly installed straps create a continuous load path from roof to foundation.

Q: How are pools integrated into a home’s structural system?

Pools often sit within perimeter stem walls and are tied into surrounding slabs and the house structure. Plumbing and electrical are roughed in before the shell is completed, and the pool deck is poured integrally so it works in unison with the home’s foundations and slabs.

Q: What should buyers look for when touring a job site?

Check for clean organization, proper reinforcement in walls and slabs, visible connection hardware (like truss straps), and documentation of inspections. Ask the builder to explain how the home is being made resistant to local environmental hazards.

Conclusion: Building with Purpose

In this stage of Building New Construction on Marco Island, the combination of filled concrete block walls, a continuous tie beam, poured columns, and truss strap hardware demonstrates a methodical approach to creating durable, storm-resistant homes. The Bartos Group and FCI Homes make these engineering choices visible and explainable to prospective buyers, which helps demystify construction for homeowners who want assurance that their investment will stand up to local conditions.

As the project moves to roof installation and enclosure, observers will begin to see the house take its final form. For now, the walls are up—and that’s a promising sign that the build is progressing on schedule and with an eye toward longevity and safety.

Contact Us Today! |

|

Providing you the experience you deserve! |

| Click me |